Paste Kettle Manufacturer

Home / Paste Kettle

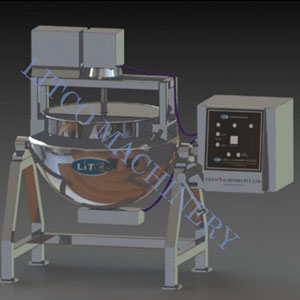

Correct mixing with homogenization is of epitome importance when it comes to the various range of products required in the Pharmaceuticals, Chemicals, Food and Cosmetics industry. The Paste Kettle is the perfect machinery for paste preparation which is an important aspect in the Granulation Line. The Paste Kettle is a universally accepted machinery which delivers homogeneous and uniform mixing and paste preparation, thereby leading to the formation of the required product.

The LITCO Paste Kettle Manufacturer is also known as Starch Paste Kettle confirms to all cGMP norms promising the desired result of paste preparation that will help you obtain your desired product. We are the renowned manufacturer of Paste Kettle in Kolkata, Bihar, Odisha, Jharkhand-India

Working Principle Of Paste Kettle

The kettle has a unique design comprising of a jacketed hemispherical bowl. Steam is passed through the jacket in order to melt the product into paste. The agitator from the top aids to the homogeneous mixing of the paste which results in the formation of a homogeneous paste suitable for further drying and processing in the Granulation Line. The kettle is also supported by a special tilting design which helps the produced paste to discharge with ease.

Special Features:

- All contact part made of SS 316 as per GMP standard.

- Hemispherical design for proper mixing paste.

- Jacket provided with steam/thermic/fluid heating arrangement.

- Driven via motor and gear box assembly mounted on top.

- Tilting arrangement for kettle is provided for discharge for starch

- paste.

- Heating insulation provided to avoid heat loss.

- Anchor type impeller design for proper mixing of paste.

- Safe earthing system.

- Available in Size from 50 to 250 Litres.

| TECHNICAL SPECIFICATIONS | ||||

| MODEL | LPK-50 | LPK-100 | LPK-200 | LPK-250 |

| Capacity | 50 Litres. | 100 Litres. | 200 Litres. | 250 Litres. |

| Gross Capacity | 60 Litres. | 120 Litres. | 220 Litres. | 280 Litres. |

|

MOC |

·All Contact Parts SS316 ·All Non-Contact Parts SS304 |

·All Contact Parts SS316 ·All Non-Contact Parts SS304 |

·All Contact Parts SS316 ·All Non-Contact Parts SS304 |

·All Contact Parts SS316 ·All Non-Contact Parts SS304 |

| Jacket Material | Water | Water | Water | Water |

| Heating Element | Electrical Heater | Electrical Heater | Electrical Heater | Electrical Heater |

| Material of Insulation | Glass Wool | Glass Wool | Glass Wool | Glass Wool |

| Insulation | 50 MM | 50 MM | 50 MM | 50 MM |

| Agitator | Top Fixed Anchor Type | Top Fixed Anchor Type | Top Fixed Anchor Type | Top Fixed Anchor Type |

| Temperature Sensor | SS PT100/PT110 Sensor | SS PT100/PT 110 Sensor | SS PT100/PT 110 Sensor | SS PT100/PT 110 Sensor |

|

Motor |

0.5 HP, 1440 RPM, TEFC, ISI make motor | 1 HP, 1440 RPM, TEFC, ISI make motor | 1 HP, 1440 RPM, TEFC, ISI make motor | 1 HP, 1440 RPM, TEFC, ISI make motor |

| Power Supply | 415 V / 50 Hz/3 Ph/AC | 415 V / 50 Hz/3 Ph/AC | 415 V / 50 Hz/3 Ph/AC | 415 V / 50 Hz/3 Ph/AC |

| Gear box | 15 RPM – OUTPUT CPEC / | 15 RPM – OUTPUT CPEC / | 15 RPM – OUTPUT CPEC / | 15 RPM – OUTPUT CPEC / |

| A.C. Drive | As per Customer’s requirement | As per Customer’s requirement | As per Customer’s requirement | As per Customer’s requirement |

| Control Panel | Standard with Push Button | Standard with Push Button | Standard with Push Button | Standard with Push Button |

|

Mounting Structure |

·SS-304 Structure with Square Pipe ·Mechanism enclosed in elegant cabinet |

·SS-304 Structure with Square Pipe ·Mechanism enclosed in elegant cabinet |

·SS-304 Structure with Square Pipe ·Mechanism enclosed in elegant cabinet |

·SS-304 Structure with Square Pipe ·Mechanism enclosed in elegant cabinet |

| Tilting Mechanism | Front Worm Type Tilting Mechanism | Front Worm Type Tilting Mechanism | Front Worm Type Tilting Mechanism | Front Worm Type Tilting Mechanism |

| Surface Finish | Mirror Finish | Mirror Finish | Mirror Finish | Mirror Finish |

Quick Links

- Octagonal Blender

- Tablet Line

- Vacuum Trasnfer System

- Roll Compactor

- Communiting Mill

- V Type Blender Machine

- Vibro Sifter

- Tablet Press Machine

- Rapid Mixer Granulator

- Planetary Mixer

- Paste Kettle

- De Duster

- Oscillating Granulator

- Mass Mixture Machine

- Multimill

- Fluid Bed Dryer

- Double Cone Blender

- Dust Extractor

- Dies and Punches

- Co Mill

- Bin Blender

- Tablet Auto Coater