Ampoule/ Vial Packaging Line

Home / Ampoule/ Vial Packaging Line

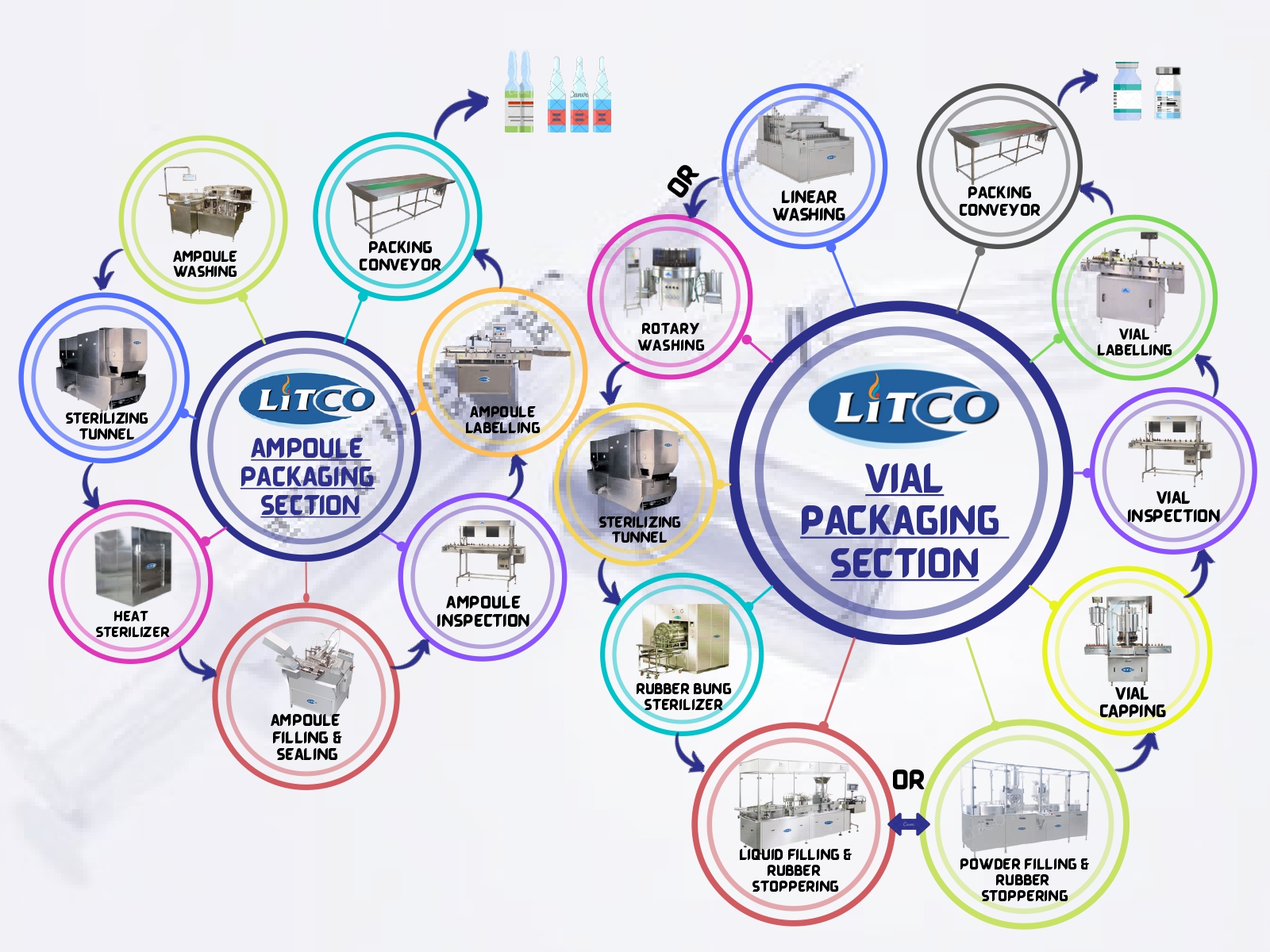

Ampoule/Vial Packaging Line with Turnkey Solutions for Pharmaceutical, Ayurvedic, Homeopathic and allied Industries by LITCO. Starting from Architectural Room design layout to final machine commissioning, with our immense experience we execute projects with excellence. All the packaging machineries are manufactured maintaining cGMP, WHO, FDA Standards that would meet the Client’s desired output both in terms of quality and quantity.

Ampoule Packaging Machinery:

- Turn Table

- Rotary Ampoule Washing Machine

- Sterilization & Depyrogenation Tunnel

- Dry Heat Sterilizer

- Automatic Ampoule Filling & Sealing Machine

- Online Ampoule Inspection Machine

- Ampoule Sticker Labelling Machine

- Packing Conveyor

Vial Packaging Machinery:

- Turn Table

- Linear Vial Washing Machine

- Rotary Vial Washing Machine

- Sterilization & Dehydrogenation Tunnel

- Rubber Bung Processor cum Sterilizer

- Automatic Monoblock Vial Liquid Filling & Rubber Stoppering

- Automatic Injectable Dry Powder Filling & Rubber Stoppering

- Automatic Vial Capping Machine

- Online Vial Inspection Machine

- Automatic Self-Adhesive Vial Labelling Machine

- Packing Conveyor

Turnkey Projects Key Features:

- Architectural Room Layout

- Production Process Layout

- Machine Design & Manufacturing

- Process Line Automation

- Clean Room & HVAC

- Electrical

- Installation & Commissioning

- Documentation & Validation

Ampoule/Vial packaging line machinery are sturdily designed and manufactured for Sterile/Injectable packaging, considering the aseptic conditions of production. As expected, sterilization is an important aspect for Ampoule and Vial Packaging section with them getting sterilized before filling and capping operation. Rubber Stoppers are often preferred in Vials so as to maintain better sealing and free of contamination. Whereas in Ampoule packaging, the Ampoules are sealed thermally. Monoblock machineries are always recommended in Vial packaging as it not only saves space but also requires less manpower to operate.

The process flow with good Production process layout is very important for improved and efficient production. A linear packaging line is mostly recommended for best packaging and cost efficiency. Air Handling Units are of utmost importance in the Technical Area to classify according to GMP Cleanroom requirements. cGMP Cleanroom Grade A to C are normally recommended for Ampoule/Vial Packaging, which is equivalent to ISO 5 to 7.

LITCO Machinery’s expertise in designing automated Process layouts along with Air Handling units for sterilized operation, helps their clients in developing the best solution for their Ampoule/Vial Packaging Line.