Oral Liquid or Syrup Processing & Packaging Line

Home / Oral Liquid or Syrup Processing & Packaging Line

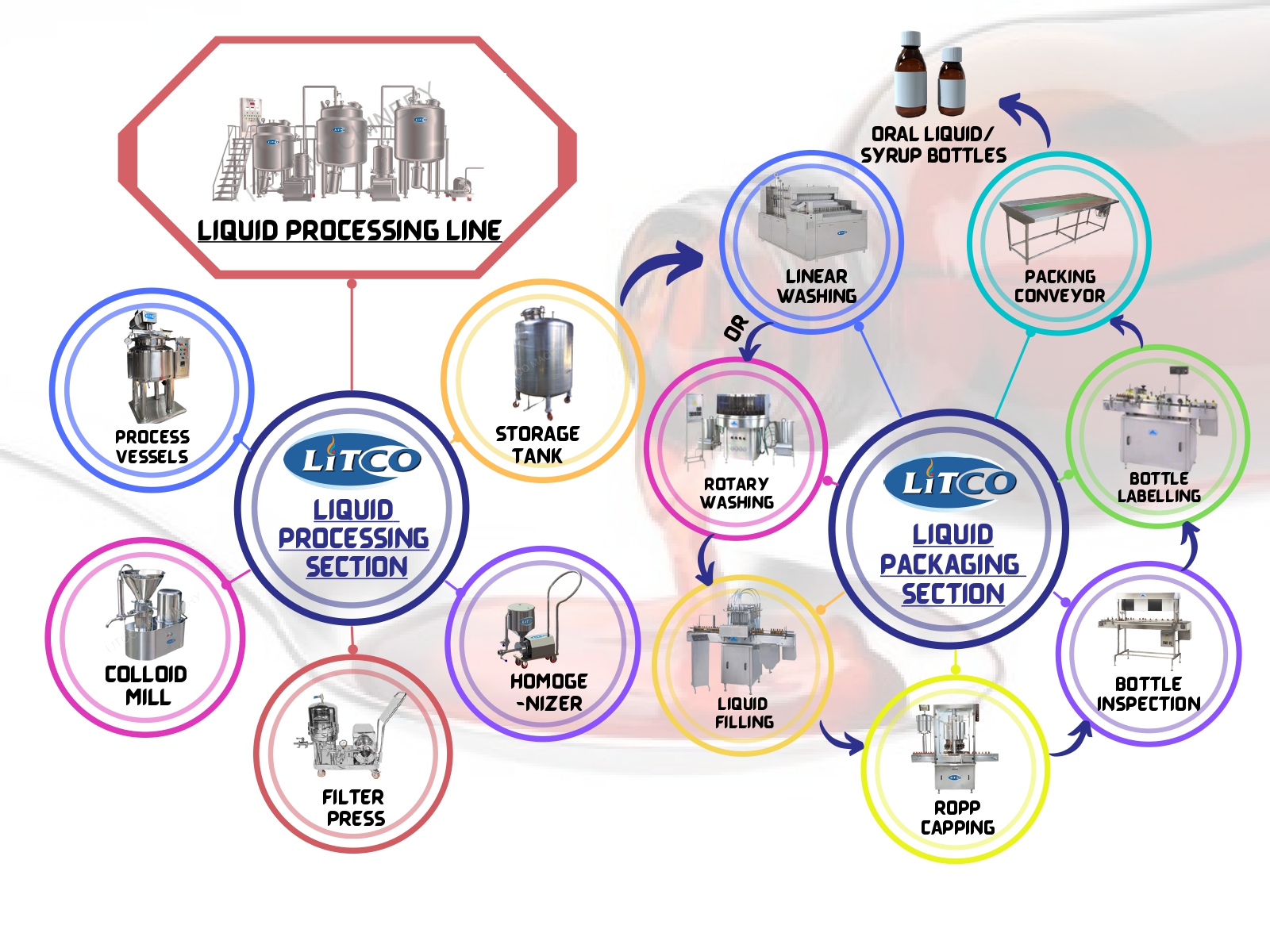

LITCO designs Oral Liquid/Syrup Processing & Packaging Line with Turnkey Solutions for Pharmaceutical, Ayurvedic, Homeopathic and allied Industries. Starting from Architectural Room design layout to final machine commissioning, with our immense experience we execute projects with excellence. All the processing & packaging machineries are manufactured maintaining cGMP, WHO, FDA Standards that would meet the Client’s desired output both in terms of quality and quantity.

Liquid Processing Section Machinery:

Liquid Packaging Section Machinery:

- Turn Table

- Linear Bottle Washing Machine

- Rotary Bottle Washing Machine

- Automatic Liquid Filling Machine

- Automatic ROPP Cap Sealing Machine

- Online Bottle Inspection Machine

- Automatic Self-Adhesive Labelling Machine

- Packing Conveyor

Turnkey Projects Key Features:

- Architectural Room Layout

- Production Process Layout

- Machine Design & Manufacturing

- Process Line Automation

- Clean Room & HVAC

- Electrical

- Installation & Commissioning

- Documentation & Validation

Oral Liquid/Syrup manufacturing requires special attention since, these are to be directly consumed by buyers. Hence, LITCO understands that its processing needs to be in a secured environment with proper mixing and adequate filtration. That is why, the jacketed process vessels, Homogenizer, Zero Hold-up Filter Presses are so designed and manufactured, that it delivers the ideal Oral Liquid/Syrup for the manufacturer.

The oral liquid/Syrup are usually packaged in bottles; hence the Bottle packaging line is sufficient for all the packaging solutions. Depending upon the demanded output, users can opt for different variants, choosing between Automatic and semi-automatic. From Bottle washing till fully filled, sealed and labeled, LITCO’s packaging section machinery is appropriate for all liquid.

LITCO Machinery’s experience in designing and developing Air Handling Units with HVAC system, helps them to create systematic Liquid Processing & packaging rooms and layouts. The process flow with good Production process layout is very important for improved and efficient production. A linear processing and packaging line is mostly recommended for most cost efficiency. Air Handling Units are of utmost importance in the Technical Area to classify according to GMP Cleanroom requirements. cGMP Cleanroom Grade A to C are normally recommended for Ointment, which is equivalent to ISO 5 to 7.

LITCO Machinery’s expertise in designing automated Process layouts along with Air Handling units for controlled operation, helps their clients in developing the best solution for their Oral Liquid/Syrup Processing & Packaging line.